Biomedical Sensors & Healthcare Parts

Processing or finishing various biomedical sensing microfluidic components

Traditional medical examination is time-consuming. Additionally, it demands a large amount of blood, which results in the loss of time. Because some diseases cannot be detected and identified immediately, immediate medical treatment cannot be provided. Additionally, some testing / examination devices occupy a large space. Their mobility is relatively low. The results of medical exams must be confirmed immediately after patients take exams or tests for specific diseases. It is critical to have sensors on the testing site to speed up medical examination. Microfluidic channels and circuits on biomedical sensors are highly diversified. Laser micro-etching and grooving could speed up their production.

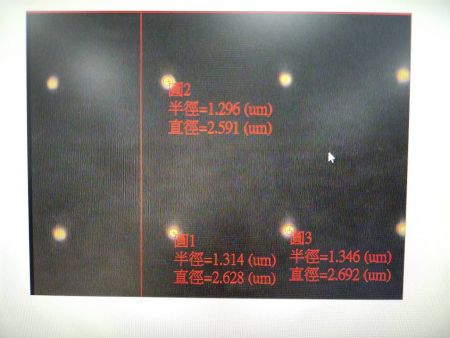

Microvias on Stainless Steel Sheets by the Laser Micro-drilling Technology

Hortech employs its laser micro-drilling technology to produce microvias on stainless steel...

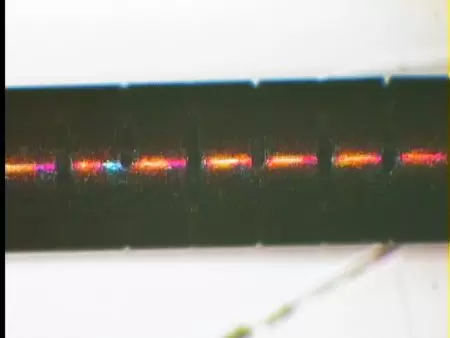

DetailsLaser Micro-cut Medical Wires & Catheters

Hortech employs the ultrafast cold laser processing along with precision motion control to cut and drill...

DetailsMicro-cutting Biomedical Films

Hortech employs laser precision micro-cutting on biomedical materials to produce microfluidic...

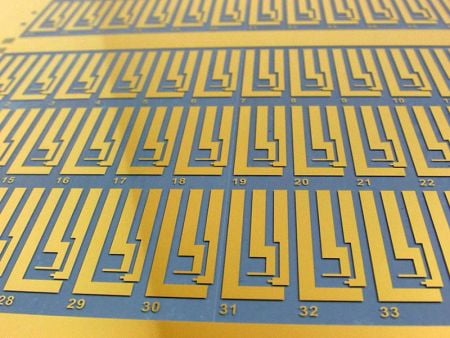

DetailsMetal and Polyethylene Terephthalate, Diabetic Blood Glucose Test Strips

The sensor is installed in medical technology or biotechnology, such as diabetic blood glucose...

DetailsLaser Micro-cutting Nozzles of Plastic Endoscopic Lens

Employing laser micro-cutting to cut sprues / nozzles is different from traditional cutting...

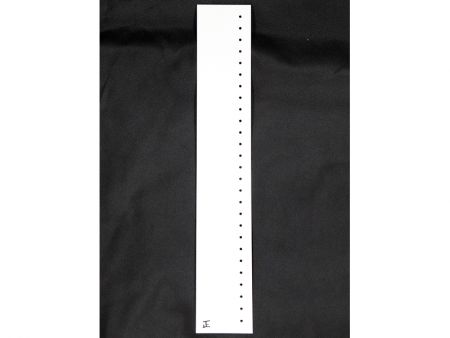

DetailsMicro-drilled Medical PET Sensing Strips

Laser micro-drilling is employed to process biomedical PET materials. Hortech focuses on the precision...

DetailsMicron Holes for Mist Sprayers

The pressure induced by medical sprayers prompts micron holes to transform the drug into mist....

DetailsBiomedical Sensors & Healthcare Parts | Laser Processing Services & Custom Designed Machines Manufacturer | Hortech Co.

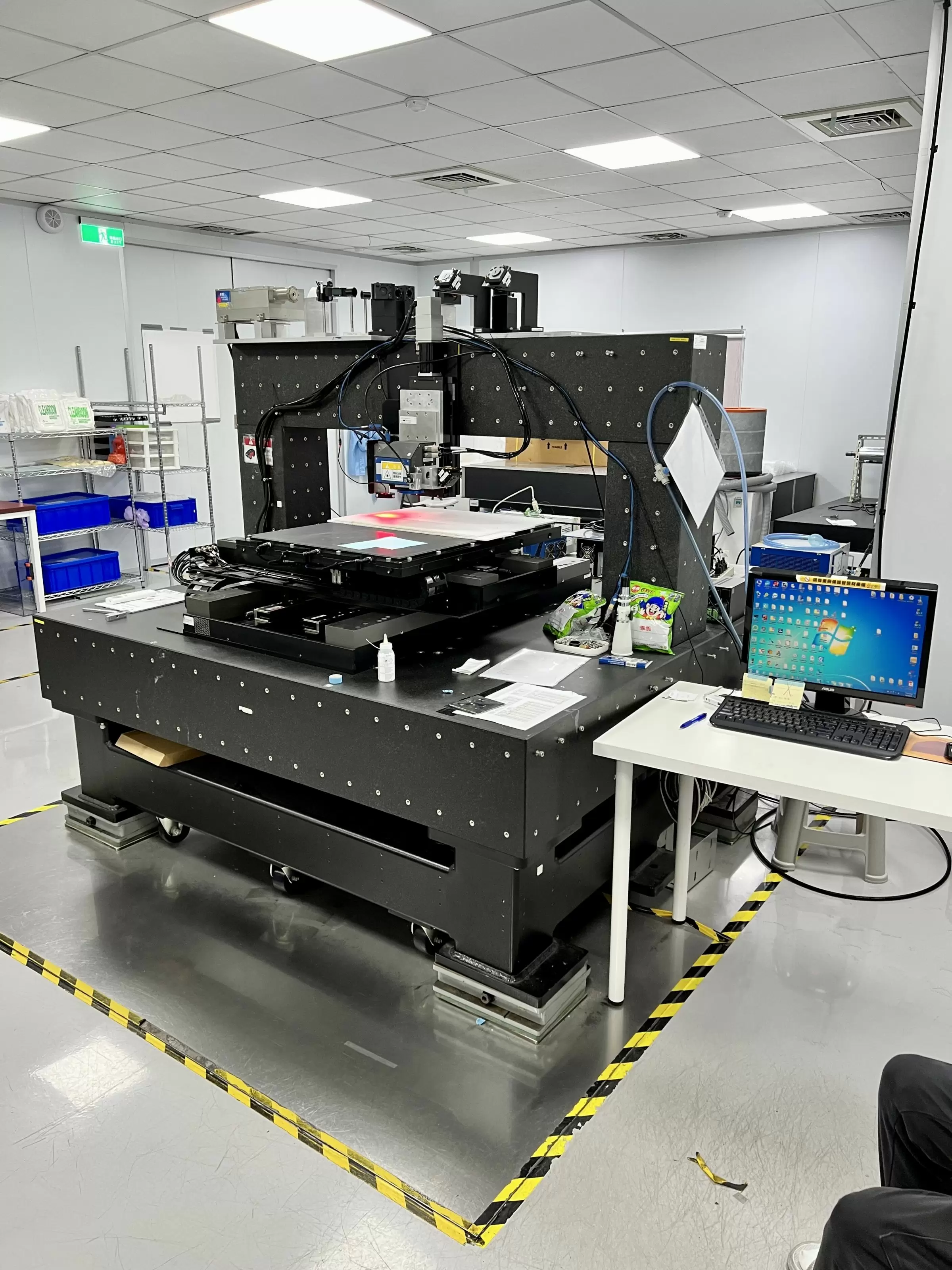

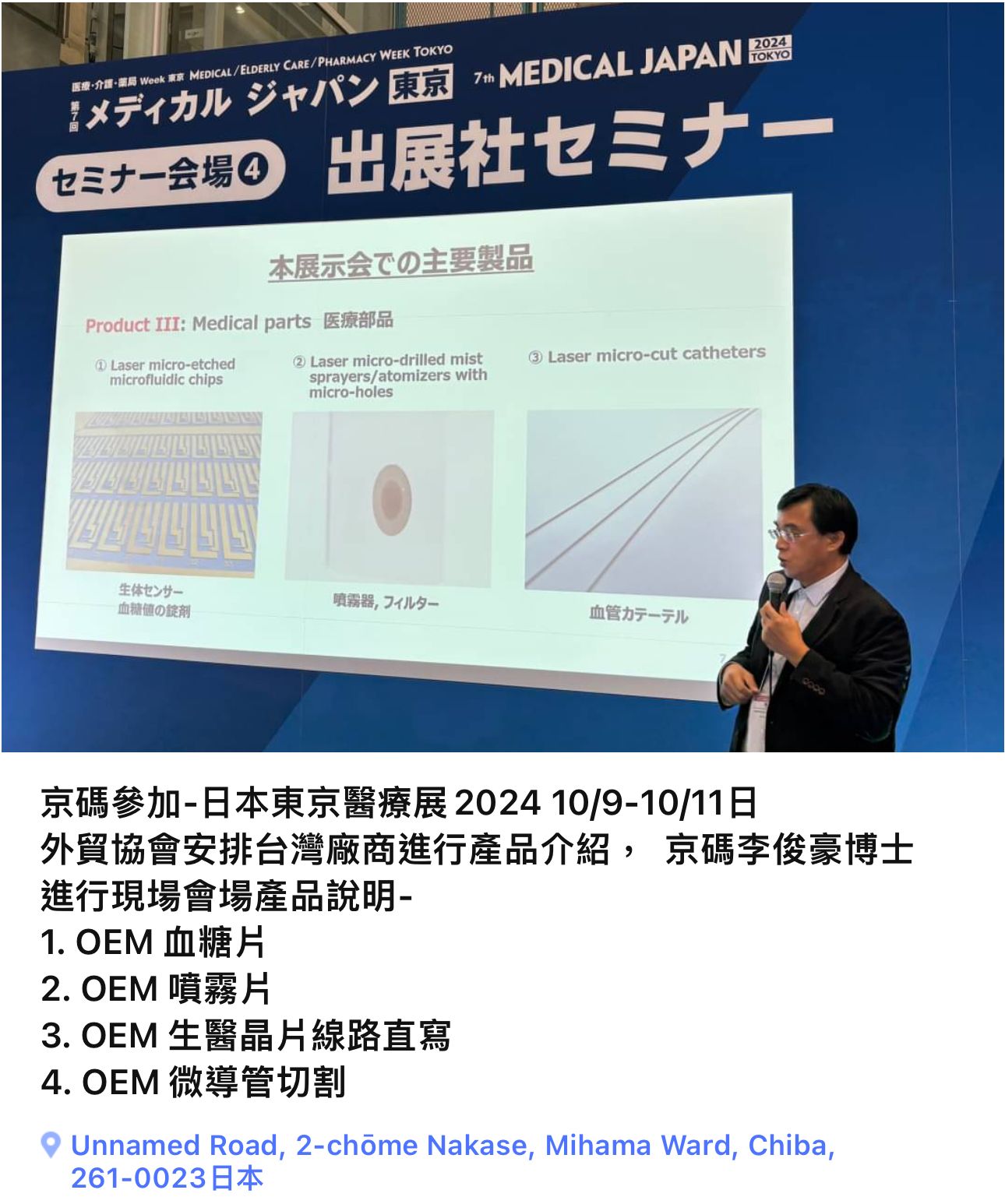

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Biomedical Sensors & Healthcare Parts, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.