Flexible & Hard Circuit Boards

Flexible and hard integrated circuit substrates

The design of circuit boards has shifted from traditional ones toward ultracompact and miniature ones for better integration with circuits of semiconductor wafers and substrate wafers or other MEMS components. This helps design and develop wearable devices and new sensors. Micron-precision laser cutting, which does not generate thermal effects, can be employed to process flexible substrates. Additionally, laser micro-drilling can be employed on wafers for 3D packaging.

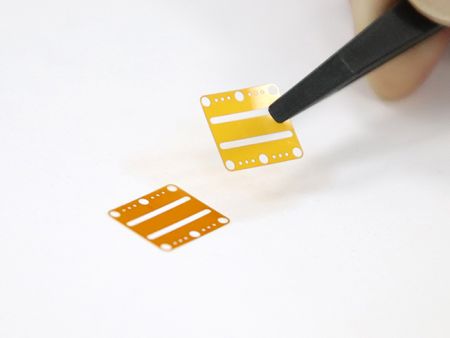

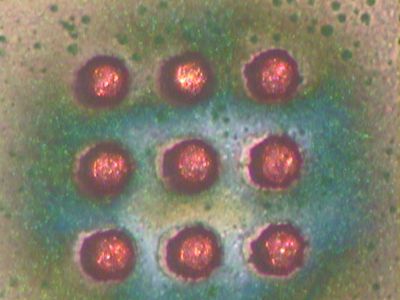

Micro-Drilled and Micro-cut, Shielded PI

Micro-drilling and micro-cutting PI materials can stand against thermal expansion. They are particularly...

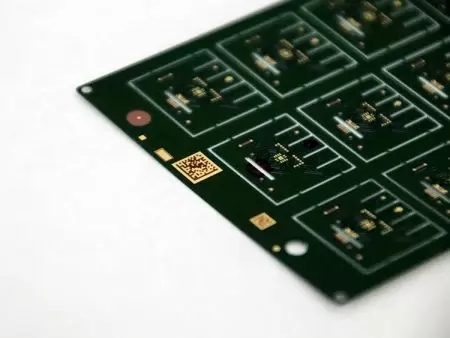

DetailsMicro-Engraved Barcodes/QR Codes on Substrates

The popularization of smartphones has facilitated the wide applications of QR codes. Users...

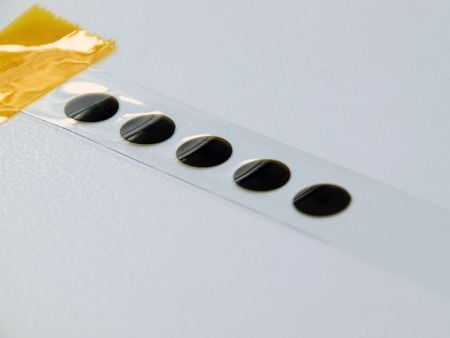

DetailsLaser Cutting PI Substrates

Applications of flexible circuit boards have become more diverse as the popularity of products...

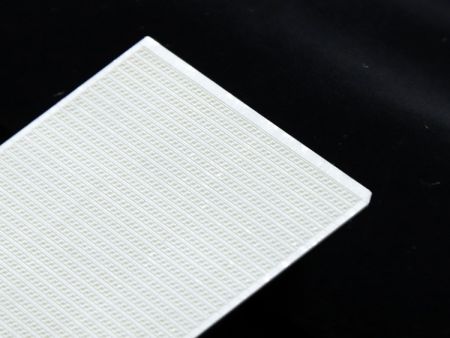

DetailsLaser Micro-drilled Protective Film-wrapped Ceramics

Protective film-wrapped ceramics need to be drilled carefully. Ceramic materials are characterized...

DetailsLaser Micro-etched Nichrome-Plated Ceramic Substrates

Since ceramic materials provide excellent insulation, they can be used to produce substrates....

DetailsFlexible & Hard Circuit Boards | Laser Processing Services & Custom Designed Machines Manufacturer | Hortech Co.

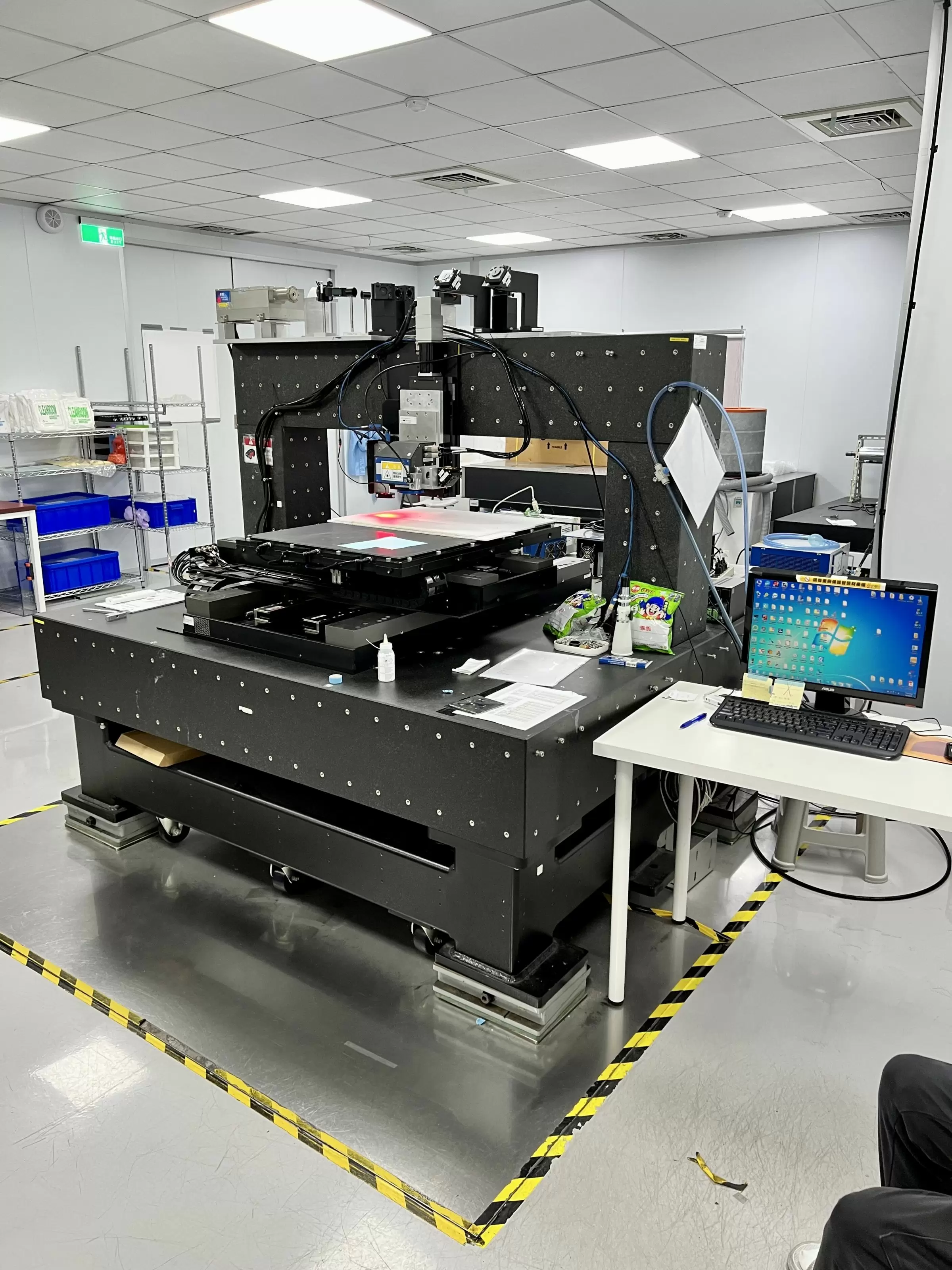

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Flexible & Hard Circuit Boards, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.