Electronics and Decorative Parts

Advanced laser processed or finished products

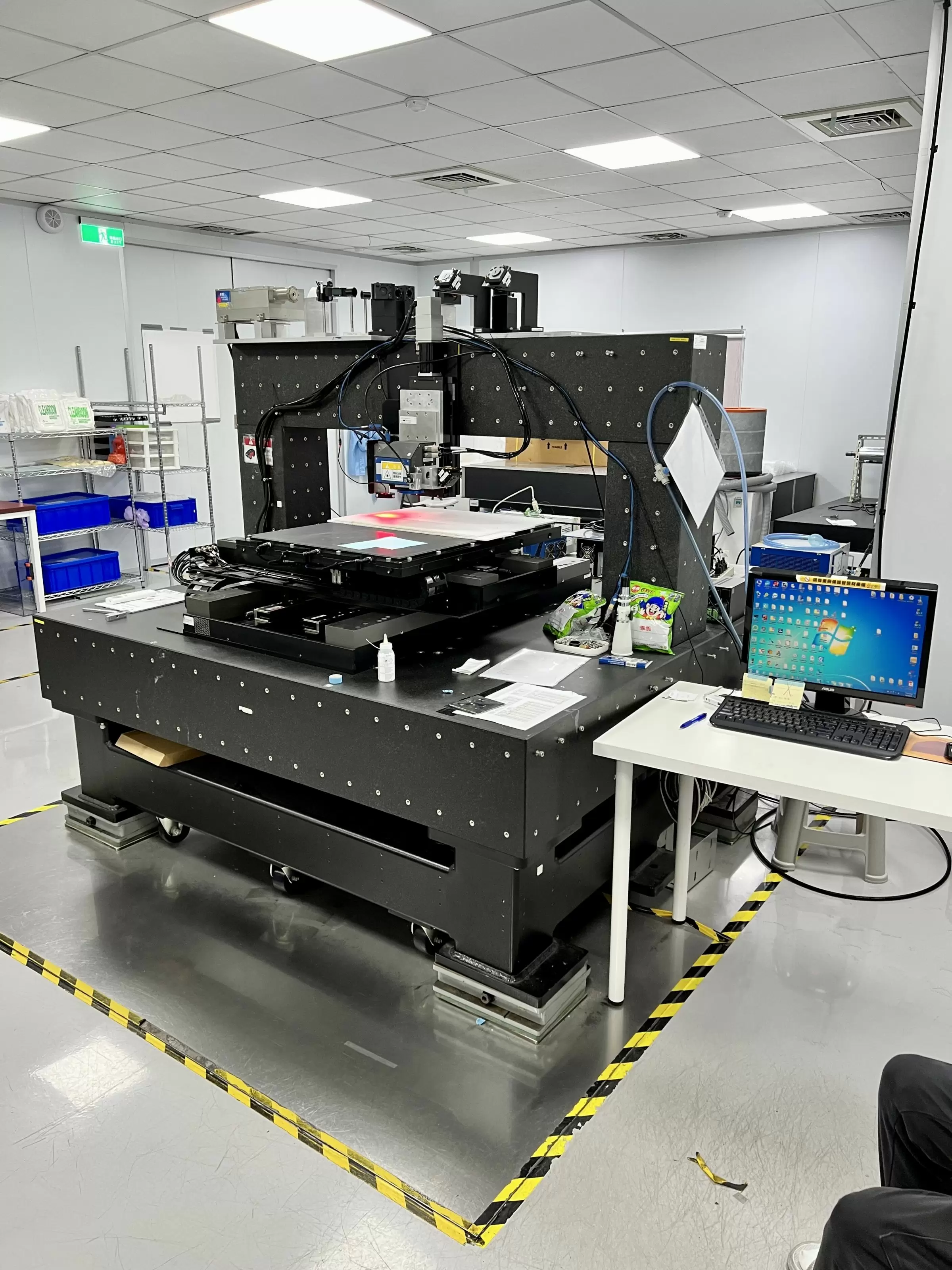

Hortech's micron laser solutions and self-developed laser machines serve different industries. Our core techniques could replace conventional processes which produce pollutants and cause damage to the materials. These include: chemical etching being replaced by laser micro-etching, CNC or die cutting being replaced by laser micro-cutting, and machine drilling being replaced by laser micro-drilling, laser hardening, laser surface microtexturization / microstructure, laser welding, and laser coating, etc. Hortech's new laser technologies not only solve the above problems, but also generate high-scale production with high yield rates.

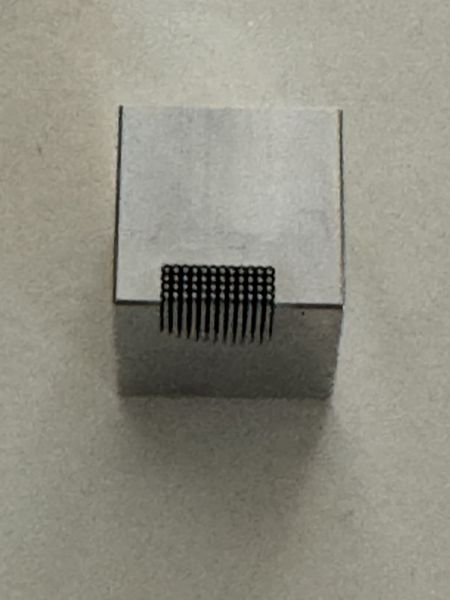

Laser Micro-drilling on Stainless Steel

Hortech employs its laser micro-drilling technology to produce microvias on stainless steel....

Details3D Laser Printing Services

Hortech provides 3D laser printing services that mass produce parts and products in consumer...

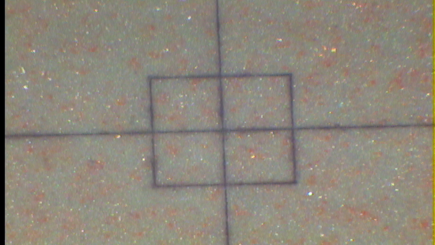

DetailsInvisible Laser Engraved Patterns on Light-control Acrylic

Hortech can laser engrave invisible patterns on specific materials for you. You may ask us to engrave...

DetailsAluminum Heat Sink with High Efficiency

Hortech can manufacture heat sinks in different shapes for our clients. The minimum linewidth...

DetailsLaser Micro-Engraved Miniaturized QR Codes on Rings

Hortech used its self-developed laser machine to laser micro-engrave miniaturized, tiny QR codes...

DetailsLaser Micro-drilled Mo Parts

Hortech implements laser micro-drilling on Mo, which are critical parts of electron microscopes....

DetailsLaser Engraved Small QR Codes & Serial Number on Stainless Steel Rings

Hortech can produce miniaturized QR codes on metal rings or those made of other materials,...

DetailsRoll-to-roll (RTR) Laser Cutting for PET Protective Films

To cut roll-to-roll PET protective films, Hortech develops the precision rotary motion platform...

DetailsLaser Curve-Cutting on Flexible Explosion-proof Films

Many devices, equipment, and gears demand curved surfaces, including wearable devices, AR/VR/MR/XR...

DetailsMicrotexturization/Microstructurization on Metal Brand Logo Surface

The smooth surfaces of different materials prevent them from adhering to each other tightly....

DetailsLaser Micro-cutting Plastic Nozzles

General or optical plastic injection manufacturers need their sprues / nozzles to be cut. Traditional...

DetailsLaser Micro-etched Screw Surface

Many rugged metal tools need to be of high hardness or high toughness, which prolongs their...

DetailsElectronics and Decorative Parts | Laser Processing Services & Custom Designed Machines Manufacturer | Hortech Co.

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Electronics and Decorative Parts, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.