Hortech's Overview

Precision Laser Processing & Finishing Services, Custom Designed Laser Machines at Micron and Sub-micron Levels

Hortech is located at Hsinchu Science Park, Taiwan, R.O.C. We are dedicated to becoming a leader in smart laser manufacturing. It designs precision laser machines and production lines for its clients to enhance productivity and efficiency. Hortech also devotes itself to manufacture key parts based on its self-developed laser technologies in the following areas, including: digital health and precision medicine, silicon photonics and optical communication, advanced semiconductor packaging, robotics, smart agriculture and fishing, and electric and autonomous vehicles.

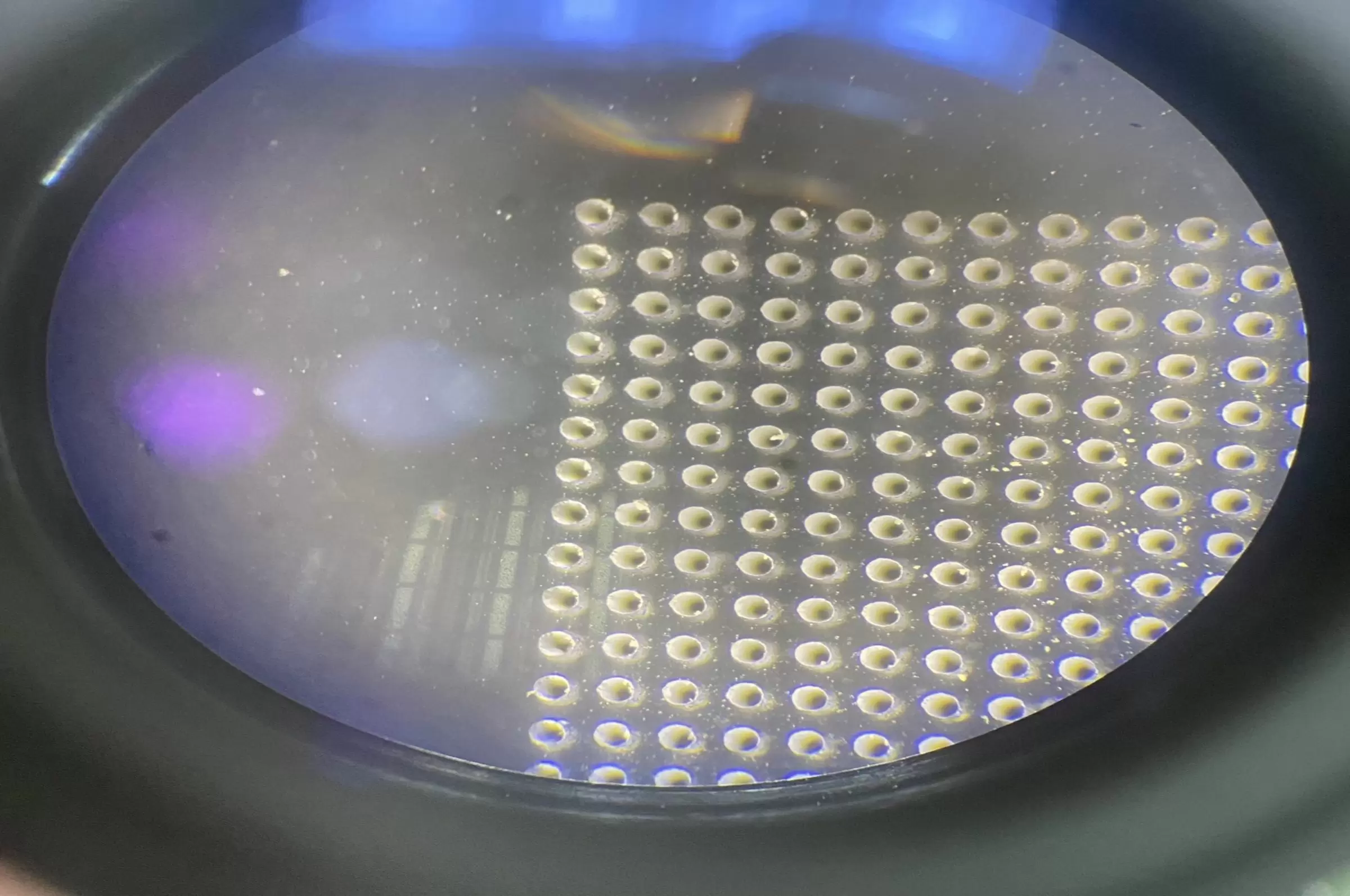

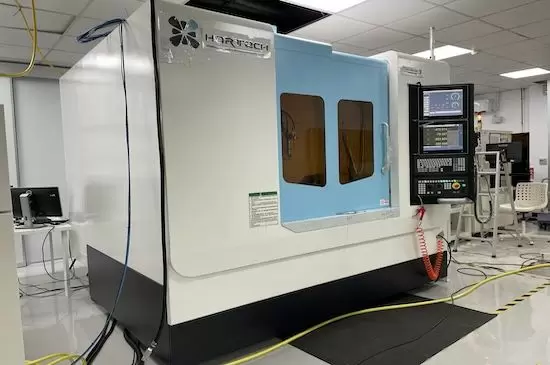

Hortech provides micron laser solutions. We specialize in laser etching, drilling, cutting, and engraving at both micron and sub-micron levels. We develop precision laser machines by ourselves to provide laser processing and finishing services. You can ask us to produce heterotypic microvia patterns on specific materials, form circuits, or micro-structurize or micro-texturize your materials. We also design precision laser systems and machines that achieve stable mass production for manufacturers in diverse industries. As well, we provide precision CNC machining services. We are capable of combining and optimizing the precision CNC machining and laser processes. Hortech works closely with industrial partners from around the world. We embrace innovation, collaboration, and partnership.

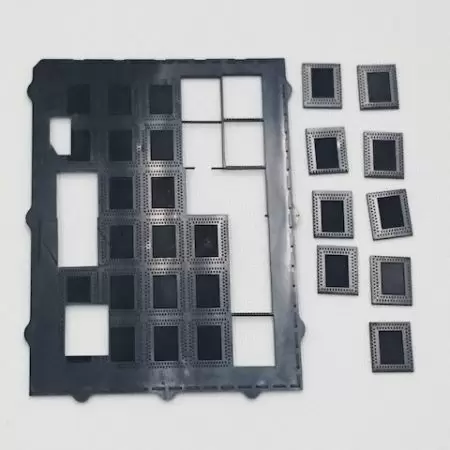

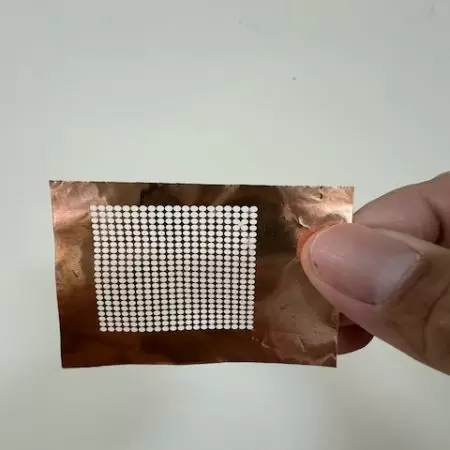

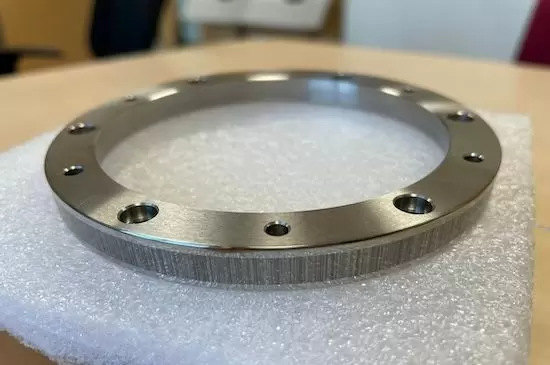

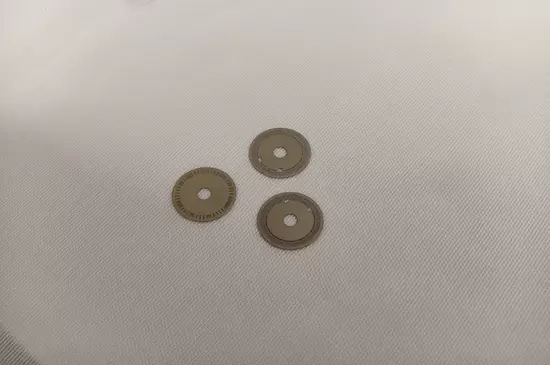

Currently, Hortech manufactures and provides laser processing & finishing services for the following items: (1) Different types of precision scales for optical encoders, including drum scales, linear scales, and disc scales. Hortech has successfully manufactured drum scales at the precision of 10 arc second; (2) Wafer dicing, micro-drilling, and laser grooving; (3) Microtexturization or microstructuration on wafers or other materials; (4) Microvia patterning or micro-hole drilling and micro-cutting on third-generation semiconductors (chemical compound semiconductors); (5) Laser processed medical tools, parts, & gadgets, including microfluidic biomedical chips, microvia for mist inhalers and nebulizers, medical wires and catheters; (6) Semiconductor parts and fixture.

Hortech also provides production line transferring services. We help manufacturers move their production lines to other cities or countries, including moving and reinstalling different types of machines.

Hortech manufactures the following items: (1) Different types of drum scales; (2) Linear scales; (3) Optical scales for robotics; (4) Critical parts of electron beam (E-beam) semiconductor system, including Mo device with micro-holes; (5) Biomedical chips & substrates; (6) Wafer dicing/cutting & drilling for different types of materials, including silicon, GaN, GaAs, and others; and (7) Laser micro-cutting & micro-drilling for manufacturing cardiac catheters. If you wish to collaborate with Hortech on developing and producing critical parts or components, you may contact us for detailed discussions.

Hortech's Milestones

| Year | Event |

|---|---|

| 2021 | Transformed toward the precision machining industry and obtained a long-term OEM order from an European brand owner. |

| 2020 | Successfully developed the glass laser cutting system for a leading LED manufacturer. |

| 2019 | Successfully developed the large power laser drilling and cutting system for C-shaped steel. |

| 2018 | Successfully developed the production resume laser marking system for medical circuit boards. |

| 2017 | Successfully developed the three wavelength femtosecond laser system for a Singapore manufacturer. |

| 2015 | Successfully developed the additive manufacturing laser system (metal powder 3D printer) with a robotic arm. |

| 2015 | Successfully developed the 0.42 mm DITO glass laser patterning system. |

| 2011 | Successfully developed the dual stages of touch panel film narrow border circuit scribing system. |

| 2009 | Successfully developed the touch panel glass/film narrow border circuit scribing system. |

| 1989 | Successfully developed the carbon film resistors laser trimming system. |

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. Hortech has rich experiences in desinging laser systems and machines for prestigious manufacturers and industrial-academic institutions. It has developed the laser trimming system that processed carbon film resistors for a leading circuit manufacturer to produce memory modules in 1989. It further developed the circuit scribing system to process the glasses/films of touch panels with narrow borders in 2009. This was mass produced for a leading touch panel manufacturer in the world. Subsequently, it developed the 0.42 mm DITO glass laser patterning system for a leading GIS manufacturer in 2015. It has developed the laser robotic arm for the Industrial Technology Research Institute (ITRI) in 2015.

Hortech developed a laser micro-engraving system that helped track the production history of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It developed a triple wavelength laser machine for a Singapore manufacturer in 2017. It has successfully developed and produced different types of scales with high accuracy for optical encoders from 2019 to 2022. It's now working on a long-term OEM order from an European company. It continues to launch new services and machines.

- Certification

- Introduction