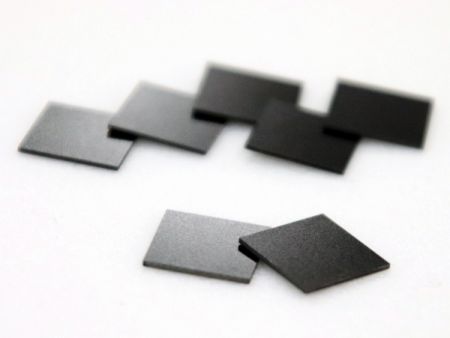

Laser Micro-cutting Fingerprint IC Substrates

Heterotypic-shape cutting on composite materials

To cut fingerprint IC substrates, Hortech coats substrates with protective films to reduce the thermal effect after the semiconductor packaging and test factory implements function tests. The protective films and the dust are then removed. Finally, the IC substrates are cut and delivered to the client.

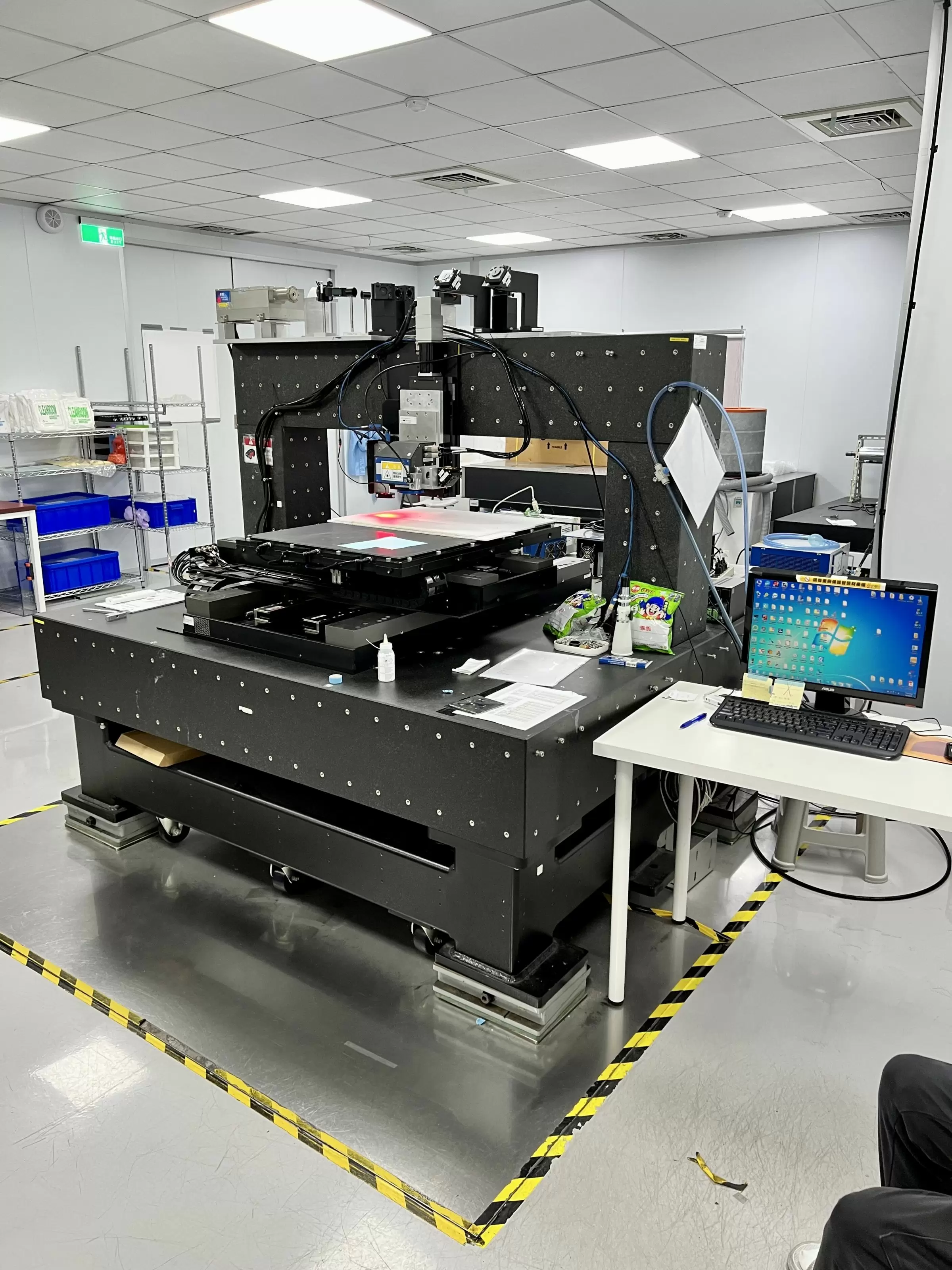

Hortech develops laser MEMS technologies to process diverse kinds of packaging. It works with giant packaging and test factories to provide quality, localized processing services. Hortech employs the high-energy laser to finish multi-layered IC substrates. Laser serves as a simple, flexible solution to finishing composite materials. These materials are cut and unique-shaped holes are produced according to the client's request. Dies and molds are not needed. Cold finishing can be employed along with the laser solution. The process can be automated. Therefore, it can complete mass production in a stable and fast way. It ensures the quality of the outcome and miniaturizes the packaging.

Traditional cutting, including die cutting, flow waterjet, and CNC router, cannot cope with multi-layered, composite materials. It not only causes ablation, but results in low precision. Furthermore, it cannot produce diverse types of shapes. Finally, the stress may cause burrs and cracks that affect circuits.

IC Substrate Laser Micro-Cutting

Different types of advanced IC packages vary in their shapes and functions. Traditional processing cannot cope with multi-layered, composite materials. It may also cause ablation. In contrast, the laser represents a flexible processing solution. Hortech adopts high-energy laser to employ cold finishing. Multi-layered, composite materials are cut and unique-shaped holes are produced according to the client's request.

Product Features

- Allow diverse patterns.

- Can package multi-layered, composite materials.

- Allow diverse product design.

Applications

- Mobile / 3C / Wearables.

- Telematics.

- Smart home devices.

Laser Micro-cutting Fingerprint IC Substrates | Laser Engraving & Micro Cutting Machines Manufacturer | Hortech Co.

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Laser Micro-cutting Fingerprint IC Substrates, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.