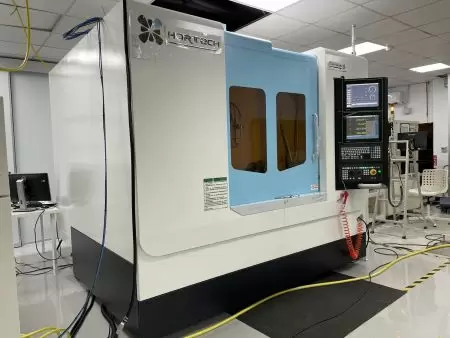

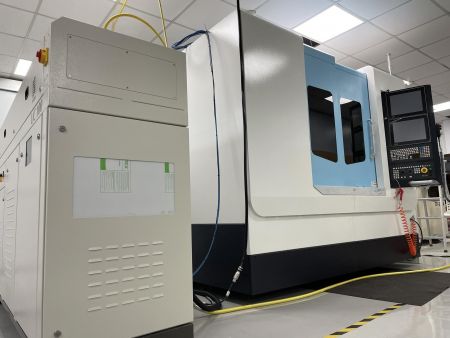

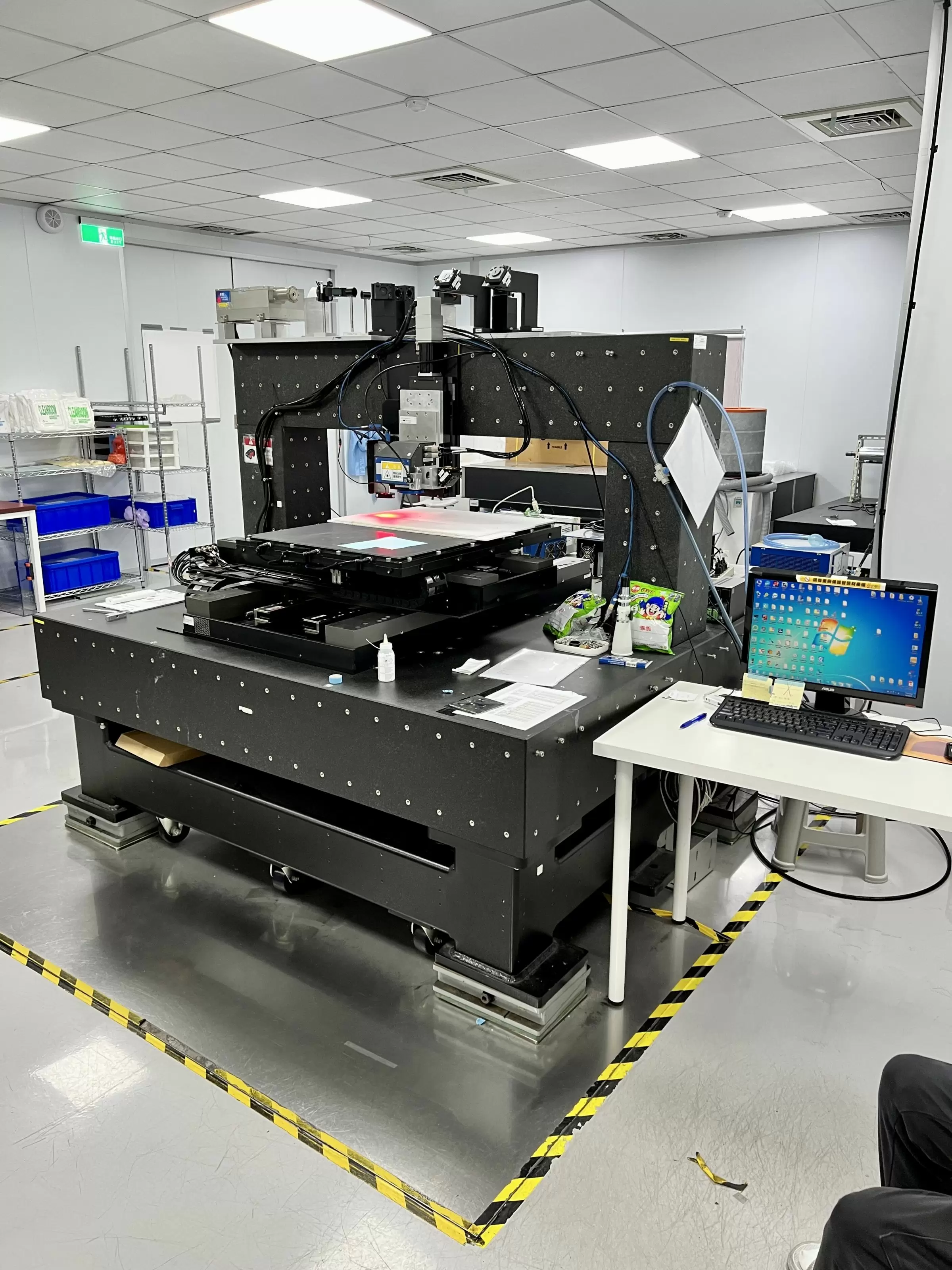

Waterjet Laser Cutting and Drilling System

Waterjet laser, laser micro-cutting, laser micro-drilling, water-guided laser machine, advanced semiconductor packaging, third-generation semiconductors, wafer dicing, wafer drilling, PCB drilling, PCB cutting, metal cutting, copper foil, vertical drilling, vertical microvias, vertical micro-holes, vertical cutting, Aluminum Silicon Carbide (ALSiC)

Hortech is pleased to announce a new collaboration with an European manufacturer. Together we introduce our latest innovation - the Waterjet Laser CNC System. This advanced system features an extensive depth of field, enabling precise micro-cutting with a high aspect ratio and deep micro-drilling. Additionally, it is capable of performing secondary processing on waste and recycled materials.

This waterjet laser system significantly reduces thermal effects and removes dust, surpassing the performance of conventional lathes and milling machines. Designed with energy efficiency and reduced carbon emissions in mind, this system sets a new standard in sustainability.

Key specifications include: (1) Precision of the motion platform: ±3 µm; (2) Custom design options available for specific requirements.

This system is suitable for processing the following materials: (1) Semiconductors: Si, Ge, SiC, GaAs, InP, GaP, CdTe, SiGe; (2) Metals: Al, Fe, Au, Ag, Cu, Mg, W, WC, Ni, Ti, Co, Cr; (3) Ceramics and other hard materials: AIN, AIO, SiN, AlTiC, ZrO, CBN, PCD; (4) Diamond and sapphire; (5) Composites: Carbon fiber reinforced composites; and (6) Plastics: Black and dark plastics.

For further information or inquiries, please do not hesitate to contact us at any time.

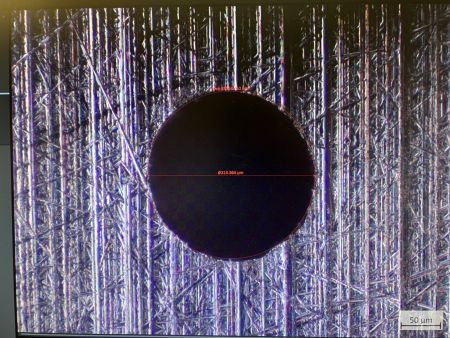

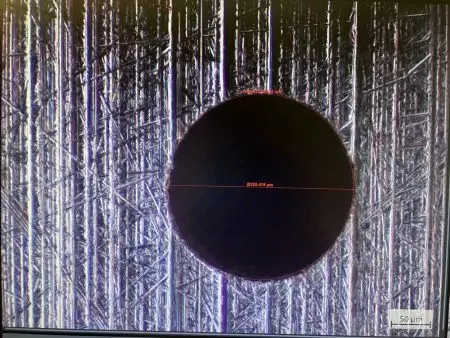

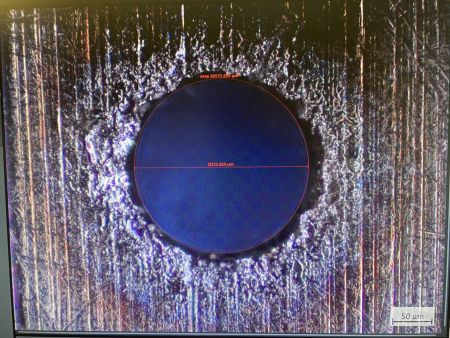

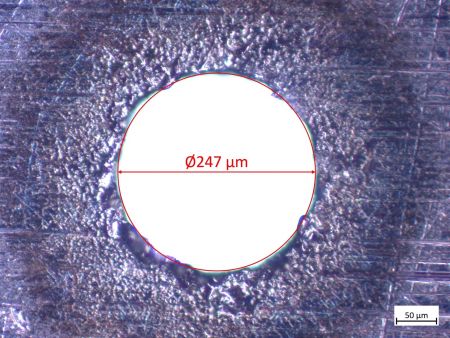

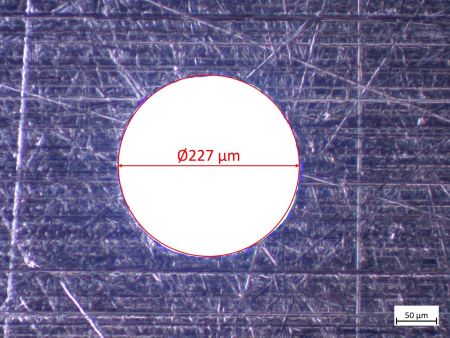

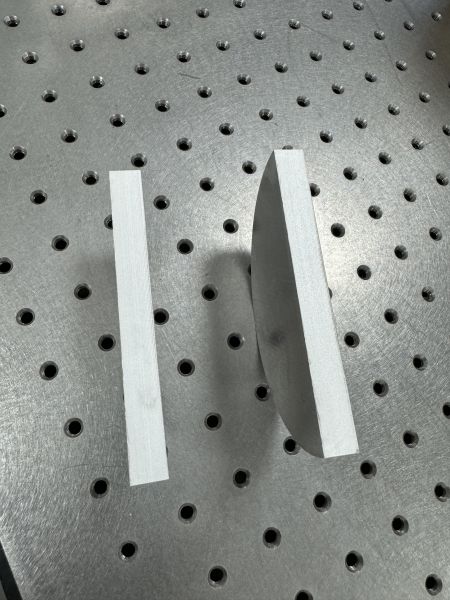

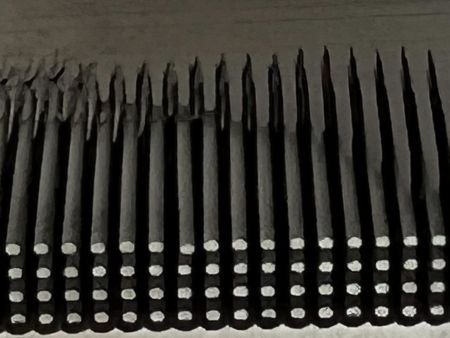

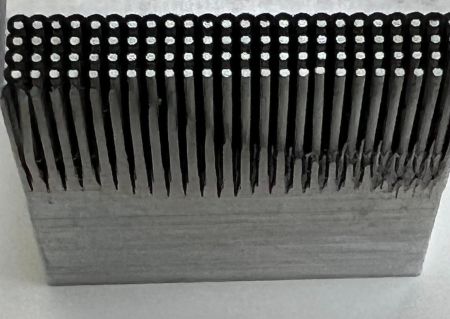

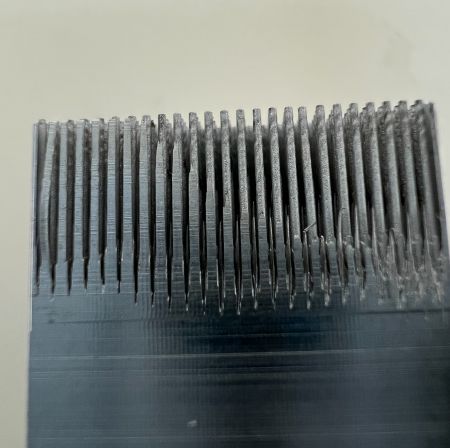

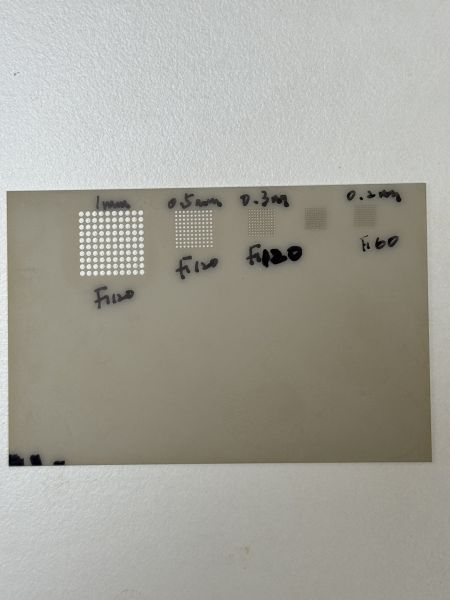

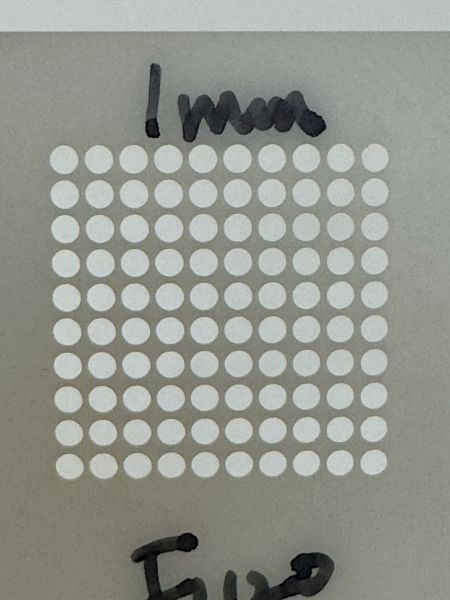

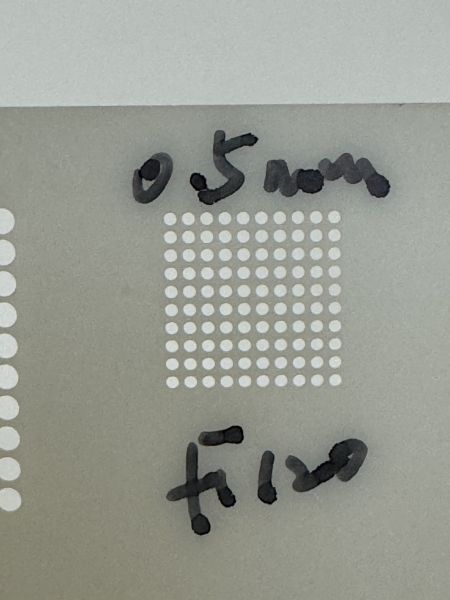

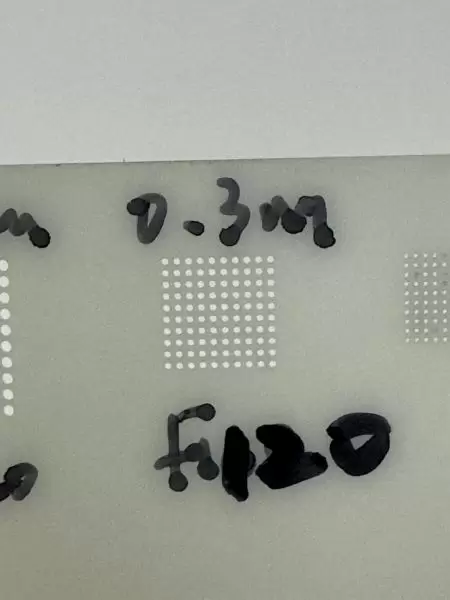

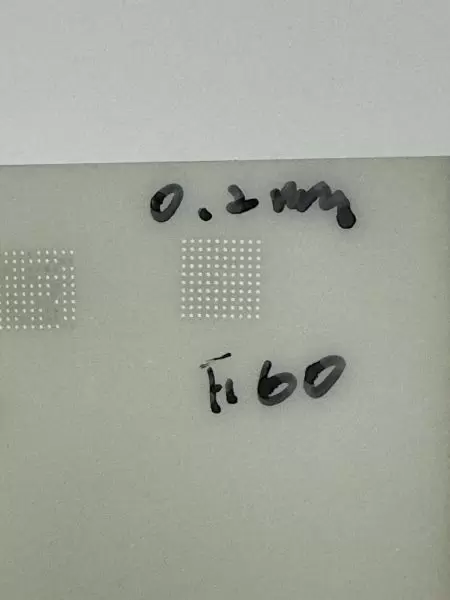

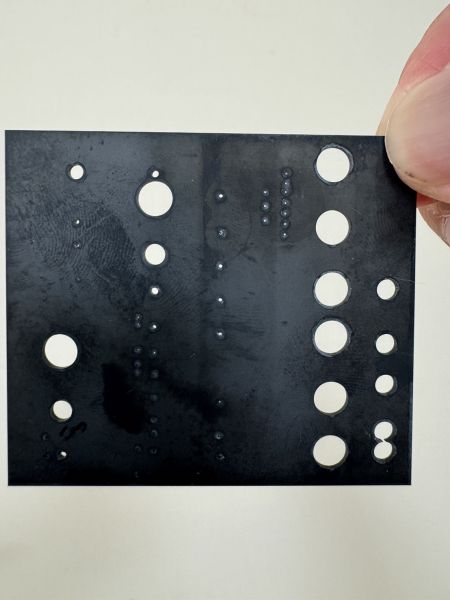

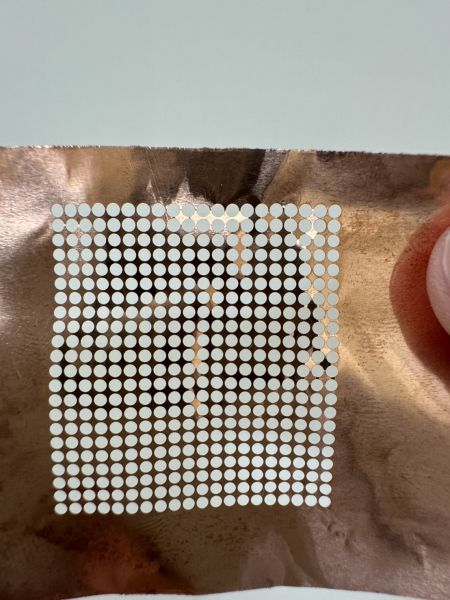

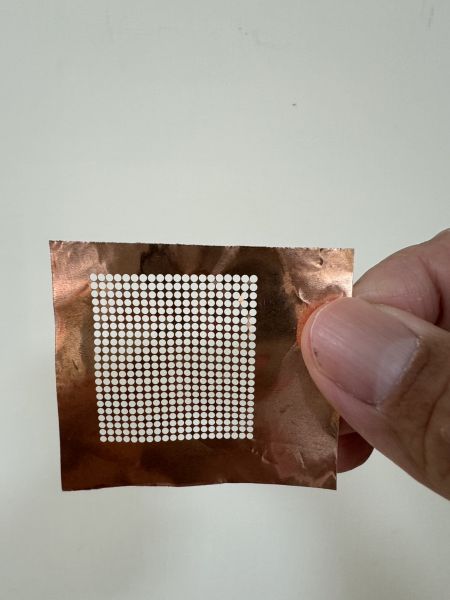

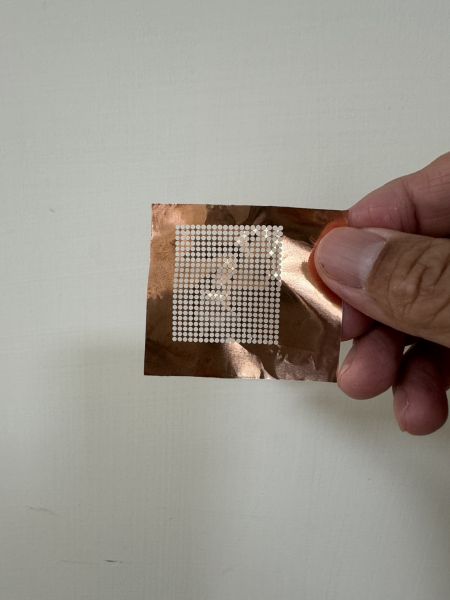

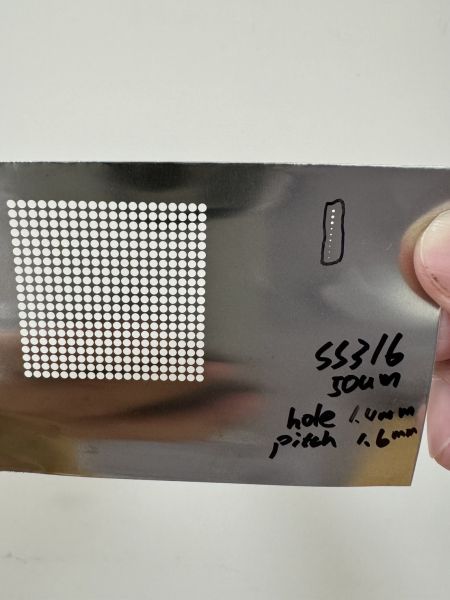

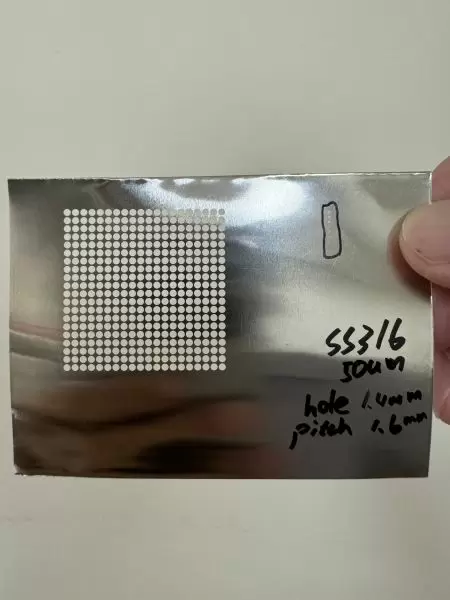

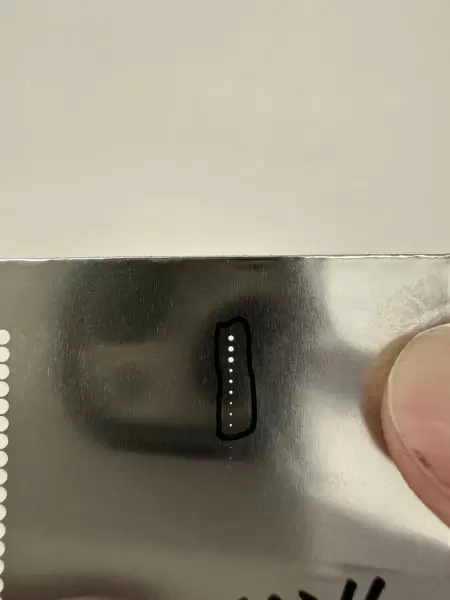

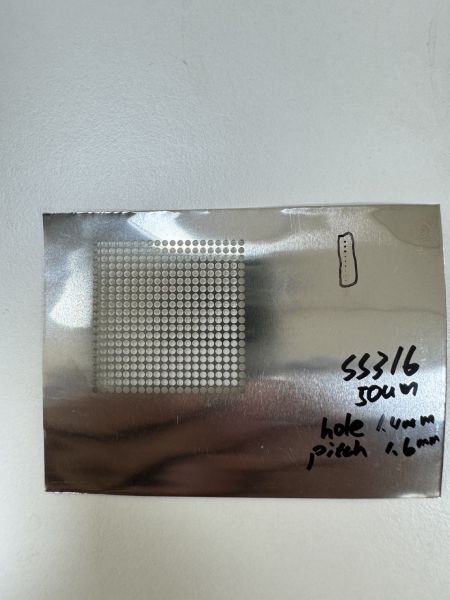

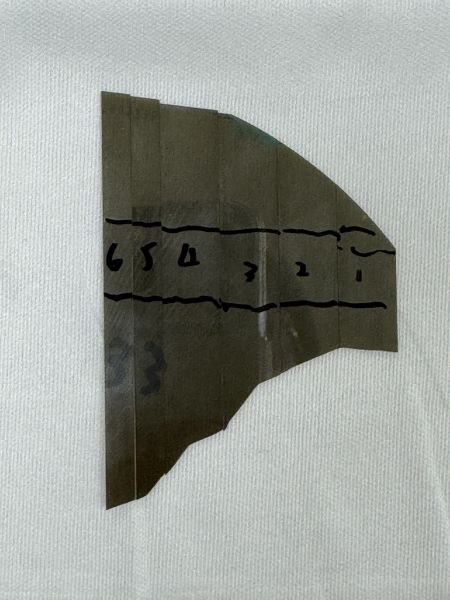

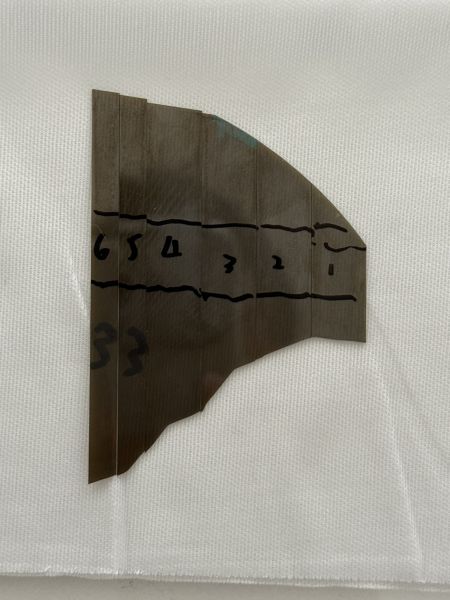

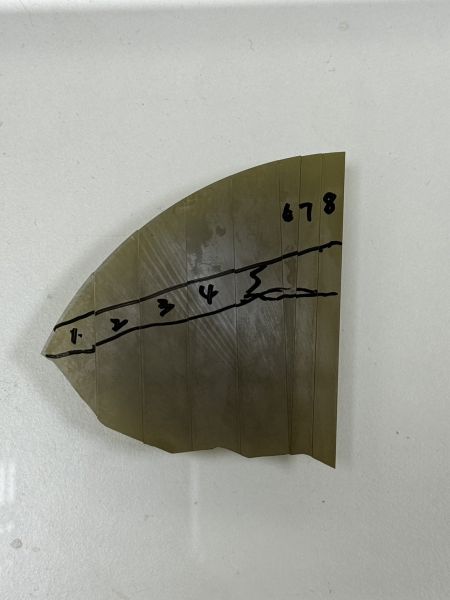

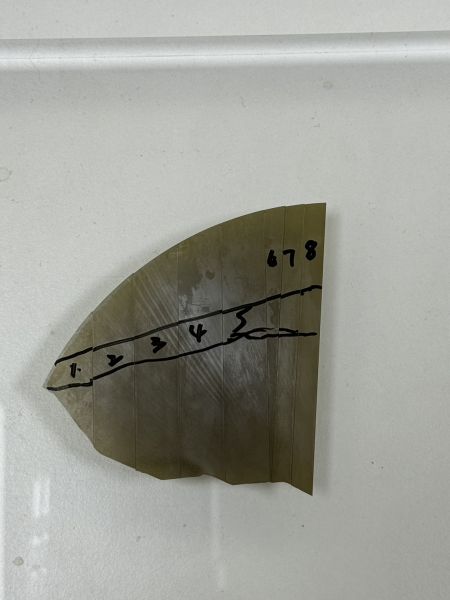

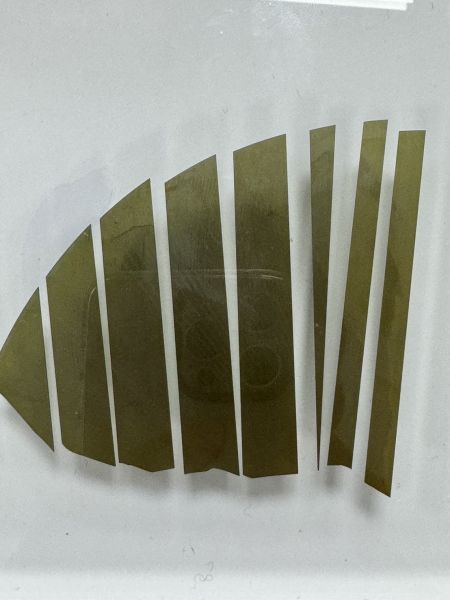

These pictures demonstrate the samples of waterjet laser cutting and drilling, including:

(1) Thick copper cutting: The thickness of the copper block is 20 mm.

(2) Stainless steel cutting: The thickness of the stainless steel block is 5 mm.

(3) Micro-drilling on stainless steel sheet: The thickness of the stainless steel sheet is 2 mm. The diameter of the micro hole is 200 µm;

(4) Vertical micro-drilling on metal sheet: The thickness of the metal sheet is 2 mm. The diameter of the vertical micro holes is 200-250 µm. The pictures demonstrate both the front and back surfaces;

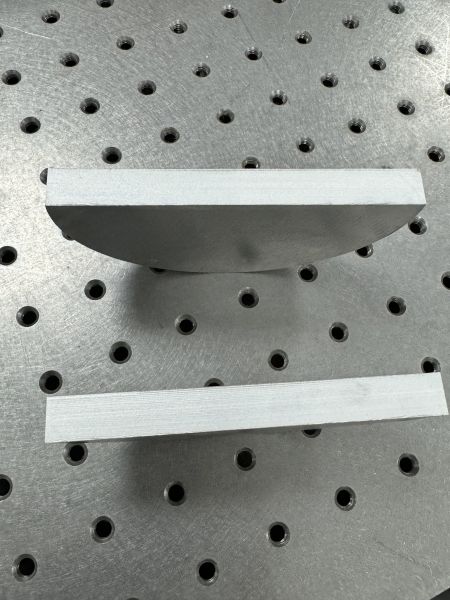

(5) Cutting aluminum alloy: The thickness of the aluminum alloy is 12 mm;

(6) Drilling Si3N4 ceramic: The thickness of the ceramic is 1 mm;

(7) Cylinder drilling on 6XXX series aluminum alloy: The diameter of the cylinder is 300 um. The depth of the cylinder is 6 mm;

(8) Vertical drilling on AIN ceramic sheet without thermal effects: The thickness of the AIN ceramic sheet is 0.37 mm. The diameters of micro-holes include 300 µm, 500 µm, and 1 mm;

(9) Vertical drilling on SiN: The thickness of the SiN is 0.9 mm. The diameters of micro-holes include 200 µm, 300 µm, and 500 µm;

(10) Vertical drilling on copper foil without thermal effects: The thickness of the copper foil is 30 µm. Hortech can perform dense micro-hole drilling based on clients’ requests. You may determine the diameters of micro-holes you wish to drill or punch;

(11) Drilling on 316 stainless steel without thermal effects: The thickness of the stainless steel is 50 µm. The micro-holes are densely drilled and the outcome is deep and vertical;

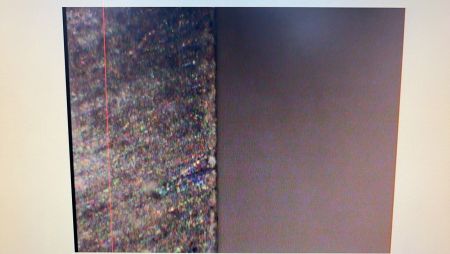

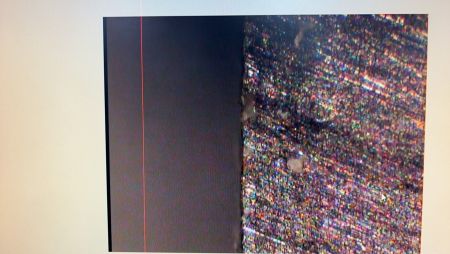

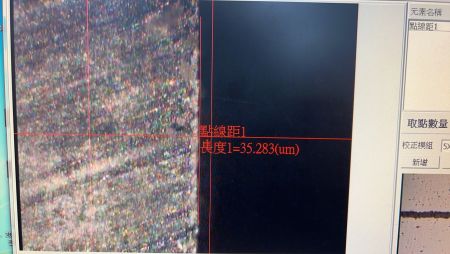

(12) Cutting silicon carbide (SiC) wafer: The waterjet laser machine does not generate thermal effect and heat when the SiC wafer. The edges are clean, smooth, and flat. The thickness of this silicon carbide (SiC) wafer is 0.43 mm. The cutting line is < 100 um.

Product Features

- Cutting brittle materials would not cause deformation, such as cutting and grinding the cooling material Aluminum Silicon Carbide (ALSiC).

- Gallery

- Waterjet Laser Copper Cutting

- Waterjet Laser Copper Cutting

- Waterjet Laser Copper Cutting

- Waterjet Laser Copper Cutting

- Waterjet Laser Stainless Steel Cutting

- Waterjet Laser Stainless Steel Cutting

- Waterjet Laser Stainless Steel Cutting

- Waterjet Laser Hole Drilling Stainless Steel

- Waterjet Laser Hole Drilling Stainless Steel

- Waterjet Laser Hole Drilling Stainless Steel

- Waterjet Laser Hole Drilling Stainless Steel

- Waterjet Laser Hole Drilling Stainless Steel

- Waterjet Laser Hole Drilling Stainless Steel

- Waterjet laser Metal Vertical drilling

- Waterjet laser Metal Vertical drilling

- Waterjet laser Metal Vertical drilling

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Aluminum Alloy Cutting

- Waterjet Laser Ceramic Drilling

- Waterjet Laser Aluminum Alloy Drilling

- Waterjet Laser Aluminum Alloy Drilling

- Waterjet Laser Aluminum Alloy Drilling

- Waterjet Laser Aluminum Alloy Drilling

- Waterjet Laser AIN Ceramic Vertical drilling

- Waterjet Laser AIN Ceramic Vertical drilling

- Waterjet Laser AIN Ceramic Vertical drilling

- Waterjet Laser AIN Ceramic Vertical drilling

- Waterjet Laser AIN Ceramic Vertical drilling

- Waterjet Laser SiN Drilling

- Waterjet Laser SiN Drilling

- Waterjet Laser SiN Drilling

- Waterjet Laser SiN Drilling

- Waterjet Laser SiN Drilling

- Waterjet Laser Copper Foil Drilling

- Waterjet Laser Copper Foil Drilling

- Waterjet Laser Copper Foil Drilling

- Waterjet Laser Stainless Steel Drilling

- Waterjet Laser Stainless Steel Drilling

- Waterjet Laser Stainless Steel Drilling

- Waterjet Laser Stainless Steel Drilling

- Waterjet Laser Silicon Carbide Wafer Dicing

- Waterjet Laser Silicon Carbide Wafer Dicing

- Waterjet Laser Silicon Carbide Wafer Dicing

- Waterjet Laser Silicon Carbide Wafer Dicing

- Waterjet Laser Silicon Carbide Wafer Dicing

Waterjet Laser Cutting and Drilling System | Laser Engraving & Micro Cutting Machines Manufacturer | Hortech Co.

Located in Taiwan since 2006, Hortech Company has been a manufacturer providing precision laser processing services and custom designed machines. Its core techniques include: Waterjet Laser Cutting and Drilling System, laser micro-etching, micro-drilling, micro-cutting, and laser engraving. It has successfully developed products for diverse industries, including optical scales for factory automation and robotics, superfine reticles for the defense industry, and wafer dicing and drilling for the semiconductor industry. Hortech's laser OEM/ODM services have served industrial partners from around the world.

Hortech Company was established by Dr. Owen Chun Hao Li in 2016. It has developed a laser marking system used for the traceability of medical circuit boards for a Taiwanese circuit manufacturer in 2018. It has developed the triple wavelength laser combined machining system for a Singapore manufacturer in 2017. It produced different types of magnetic and optical scales with high accuracy for encoders and actuators since 2019. Hortech kept upgrading its laser machines and expanding its services to different regions. Its rigorous quality control processes ensures its clients' needs are satisfied.

Hortech Co. has been offering customers ultra-precision laser machining services and laser CNC machines since 2006, both with advanced technology and 27 years of experiences, Hortech Co. ensures each customer's demands are met.